As an Amazon Associate, I earn from qualifying purchases

If you’re looking to repair aluminum, JB Weld has a solution for you. Their aluminum repair product is designed to fix cracks, holes, and other damage in aluminum surfaces. Whether it’s a car part, a household item, or any other aluminum material, JB Weld can help you make a strong and durable repair. This product is easy to use and provides a long-lasting solution for your aluminum repair needs.

Prepare the Surface: Clean and roughen the area to be repaired

Before using JB Weld to repair aluminum, it’s important to prepare the surface properly. This involves cleaning and roughening the area to be repaired. By doing this, you create a surface that allows the JB Weld to adhere securely and form a strong bond.

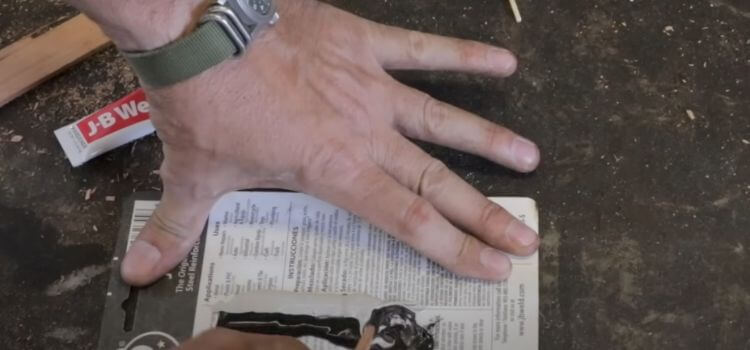

Mix the JB Weld: Follow the instructions on the packaging to ensure proper mixing

JB Weld is a strong adhesive that can be used for a variety of repairs, including aluminum. It is important to follow the instructions on the packaging for proper mixing in order to ensure that the product sets and adheres correctly. Be sure to thoroughly mix the two components according to the directions provided to achieve the best results for your repair.

Apply the JB Weld: Use a putty knife or applicator to apply the JB Weld to the damaged area

When applying JB Weld, it’s important to use a putty knife or applicator to apply it to the damaged area. This will ensure that the JB Weld is applied evenly and effectively for a strong and durable repair.

Allow to Cure: Let the JB Weld cure for the recommended amount of time

jb weld aluminum repair should be allowed to cure for the recommended amount of time as per the product instructions. This is important to ensure that the repair sets properly and reaches its maximum strength. Rushing the curing process could result in a weaker bond and may not provide the desired results. It’s best to be patient and give the JB Weld enough time to fully cure before testing or using the repaired material.

Sand and Paint (if necessary): Once the JB Weld has cured, sand down any rough edges and paint if needed

When you are working with JB Weld, it is important to remember to sand down any rough edges once the JB Weld has cured. This will help to create a smooth surface and ensure that your repair looks clean and professional. Additionally, if necessary, you can paint over the JB Weld to match the surrounding area. This will help to blend the repair into the rest of the material and make it less noticeable. Sanding and painting are important finishing touches when using JB Weld for repairs.

Test the Repair: Ensure that the repair is strong and secure before using the aluminum item again

Before using the aluminum item again, it is important to test the repair to ensure that it is strong and secure. Make sure that the jb weld aluminum repair has fully cured and hardened before putting any stress on the repaired area. You can test the repair by gently applying pressure or tapping on the repaired area to check for any signs of weakness or movement. It is also a good idea to inspect the repair visually to ensure that it is holding up well. Once you are confident that the repair is strong and secure, you can safely use the aluminum item again.

Conclusion

JB Weld offers a range of aluminum repair products that are easy to use and provide strong, durable repairs. Whether you need to fix a crack, hole, or other damage to aluminum, JB Weld has a product that can help. With the right preparation and application, you can make professional-quality repairs to your aluminum items using JB Weld products.

Related Guide:

5 best j b weld for aluminum Reviews

As an Amazon Associate, I earn from qualifying purchases

Leave a Reply