In this post, we will go through the step-by-step process of tightening wheel bearings. Whether you are a DIY enthusiast or a professional mechanic, knowing how to properly tighten wheel bearings is crucial for the safety and performance of your vehicle.

Jack up the vehicle

To jack up a vehicle, you will need to use a hydraulic jack or a bottle jack. Place it under the jacking point on the vehicle and slowly pump the handle until the vehicle is lifted off the ground. Make sure to use jack stands to secure the vehicle once it is lifted.

As for tightening wheel bearings, you will need to first remove the dust cap or hubcap from the wheel. Then, use a wrench to loosen the axle nut and remove it. Next, adjust the wheel bearings by tightening the adjusting nut while spinning the wheel until you feel a slight drag. Once adjusted, secure the nut and replace the dust cap or hubcap. It’s important to refer to the vehicle’s specific manual for detailed instructions on tightening wheel bearings.

Remove the wheel and brake caliper

To tighten wheel bearings, you’ll need to first remove the wheel and brake caliper. Then, you can access the wheel bearings for tightening. Use the appropriate tools and follow the manufacturer’s guidelines for your specific vehicle to ensure the wheel bearings are tightened correctly.

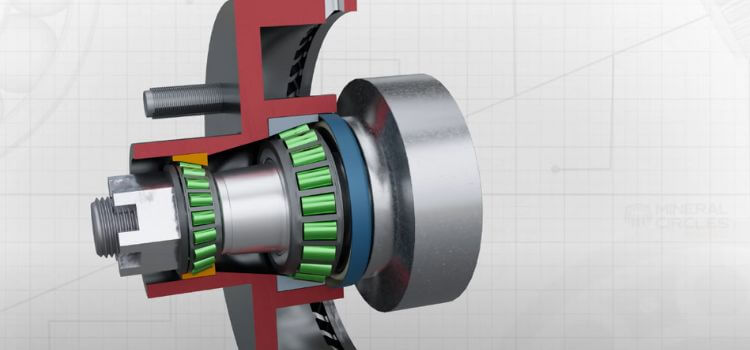

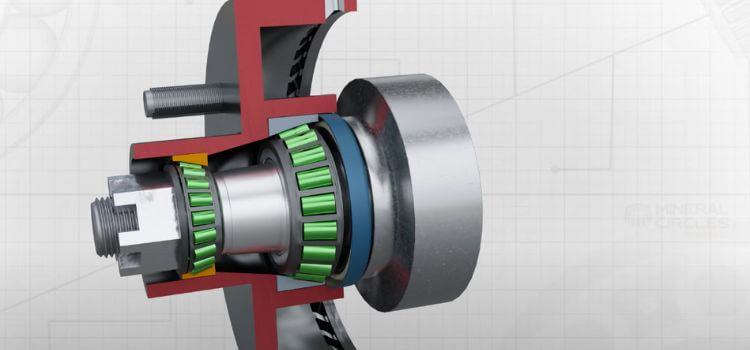

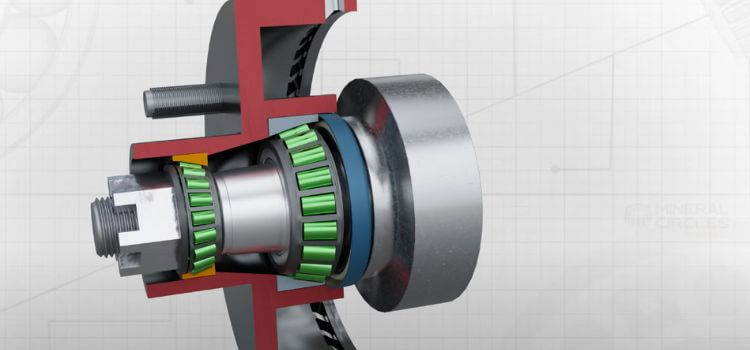

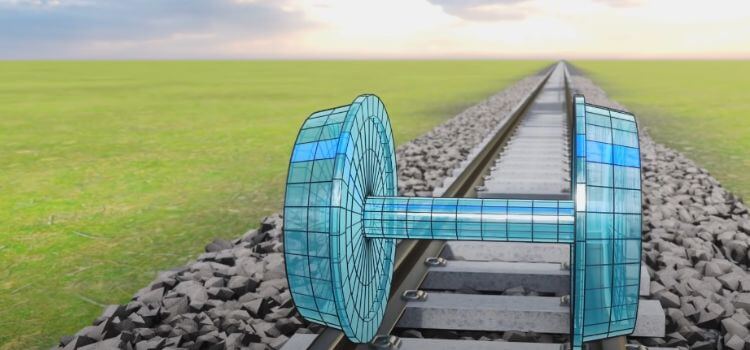

Remove the wheel hub and bearings

To remove the wheel hub and bearings, you will need to follow a step-by-step process. First, you will need to jack up the car and remove the wheel. After that, you can access the wheel hub and bearings and proceed to remove them. If you’re unsure or uncomfortable with this process, it’s best to seek professional help.

Clean and inspect the bearings

When it comes to maintaining your bearings, it’s important to regularly clean and inspect them to ensure they are in good working condition. One essential part of this maintenance is tightening the wheel bearings. It’s important to follow the manufacturer’s guidelines for tightening the wheel bearings to prevent any issues with the bearings and ensure the safety of your vehicle. Regular maintenance of your bearings will help prolong their lifespan and keep your vehicle running smoothly.

Repack the bearings with grease

Repacking the bearings with grease is an important maintenance task to ensure the smooth and efficient function of your wheel bearings. To tighten the wheel bearings, start by removing the wheel and the hub from the axle. Then, disassemble the hub and remove the old grease and bearings. Clean them thoroughly and apply a generous amount of new grease before reassembling the hub. Finally, adjust the bearing preload to the manufacturer’s specifications to ensure proper tightness. Regular maintenance of your wheel bearings will help prevent premature wear and ensure a safe and smooth ride.

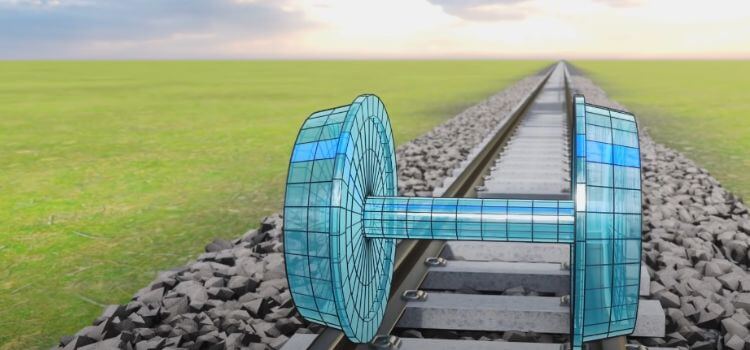

Reinstall the bearings and wheel hub

To tighten wheel bearings, you should start by removing the wheel and brake assembly. Then, use a wrench to loosen the axle nut and remove the cotter pin. Clean and inspect the bearings for any damage, and then pack them with fresh grease. Finally, replace the cotter pin and reassemble the wheel and brake assembly.

Reassemble the brake caliper and wheel

To reassemble the brake caliper and wheel, first make sure the wheel bearings are properly tightened. Ensure all bolts and fasteners are tightened to the recommended torque settings.

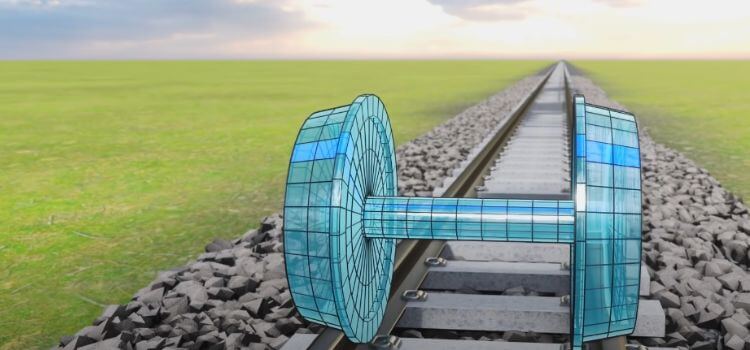

Lower the vehicle and test the wheel bearings

To tighten wheel bearings, first, you’ll need to raise the vehicle and remove the wheel. Then, use a wrench to loosen the axle nut and remove it. Next, pull the hub off the spindle and remove the outer wheel bearing. Clean and inspect the bearings, then repack them with bearing grease. Place the bearings back into the hub and reinstall the outer wheel bearing. Lower the vehicle and test the wheel bearings to ensure they are properly tightened and functioning correctly.

Conclusion

tightening wheel bearings is an important maintenance task to ensure the safety and performance of your vehicle. It’s important to follow the manufacturer’s guidelines for torque specifications and to regularly check and maintain your wheel bearings to prevent potential issues on the road. If you’re unsure about how to tighten your wheel bearings, it’s best to consult a professional mechanic for assistance.